Location

Culver City, California

Program

Office

Size

15,000 square feet

Dates

1998

Construction Systems

Individually cut concrete blocks

Key Staff

Jay Vanos, Scott Nakao, Paul Groh, Dolan Daggett, Francisco Delgado, Don Dimster. John Bencher, Stuart McGruder, Penn Ruderman, Justin Liu, Sandra Gallego, Nicole Hatje

Key Consultants

Structural: Kurily, Szymanski, and Tchirkow

Mechanical: Fruchtman and Assoc.

Electrical: Silver, Roth and Assoc.

Photographer

Tom Bonner

The Trivida office project is located in a former manufacturing zone on a site where a number of adjoining warehouses in Culver City were once served by a surface railway.

The tenant for the new space is a soft ware design company with conventional program requirements: private offices, open work and production areas, and conference space, and the need for an iconic image to symbolize the company.

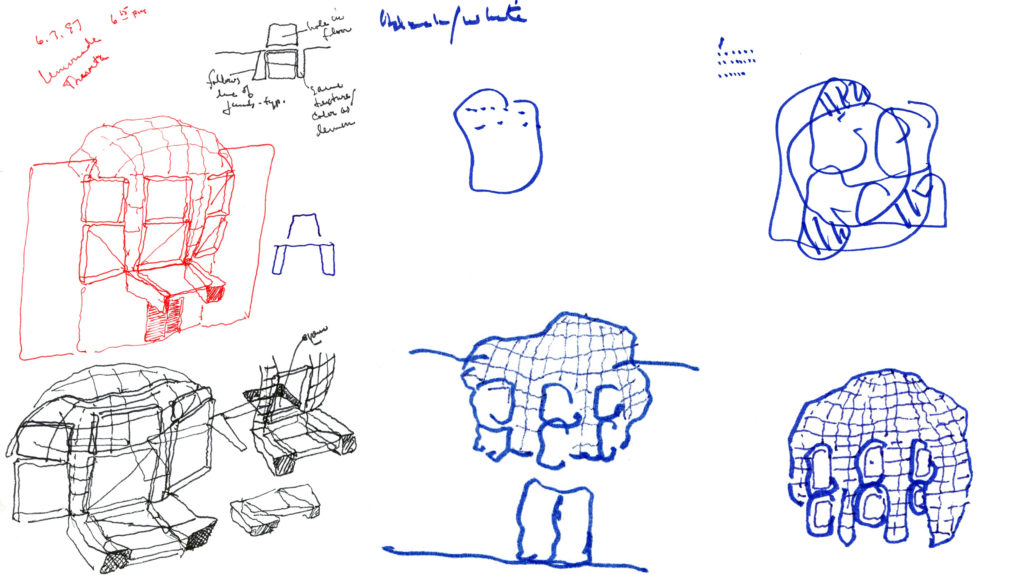

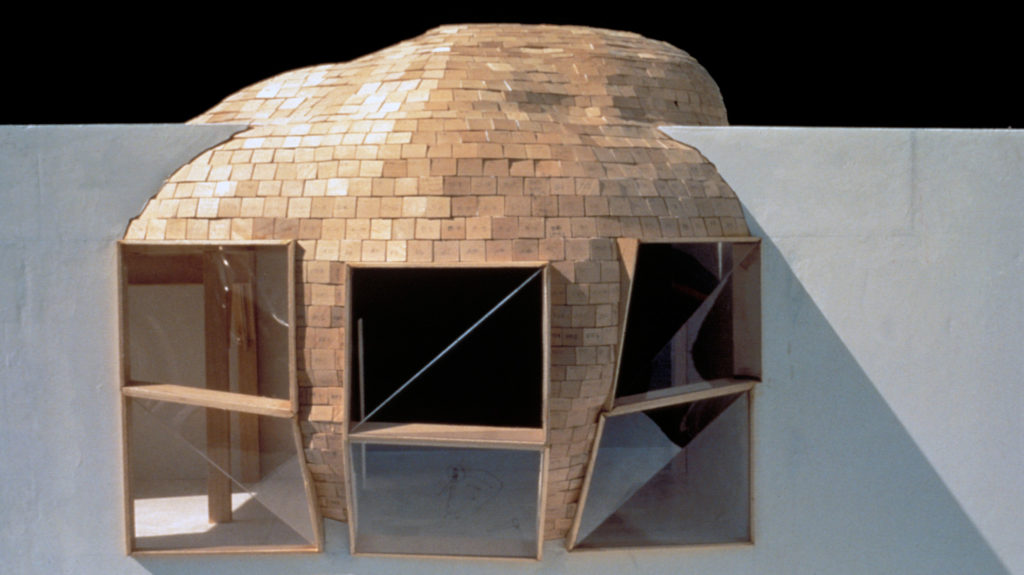

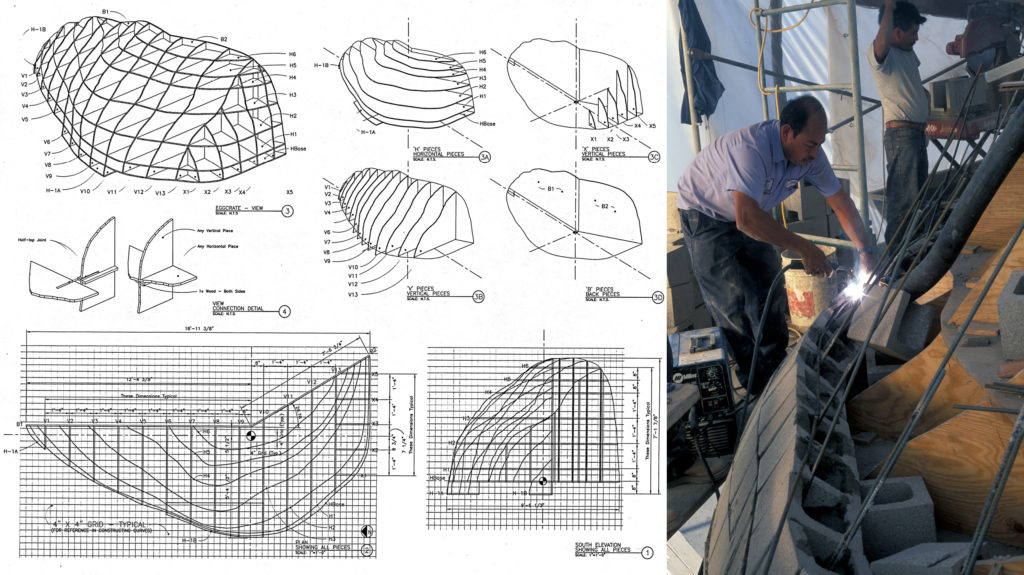

The technical and conceptual focus of the project is a 30 foot by 30 foot portion of a 165 foot long, 35 foot high, otherwise uninterrupted, cement plaster wall that faces the public entry and street. The original model studies of the Trivida wall were constructed with lemon rinds, a close facsimile to the irregular curving surfaces that identify the Trivida shape. Having arrived at the entry wall configuration, the lemon rind model was re-constructed as a sequence of rectilinear blocks, positioned to approximate the pre-determined shape of the curve. The original smooth curve was re-conceptualized with identical, pre-fabricated blocks as both wall shape and surface, to be seen identically from both inside and outside the new offices. The new, “replacement” Trivida wall that interrupts the original flat plaster surface, was constructed of exactly 1000 concrete blocks, each 8 inches by 8 inches by 8 inches. Each block is specially cut to fit within the lemon rind wall model. Each block is originally fabricated identically, but modified specifically in each case to fit the varying curvature of the new wall.

The blocks are supported on a framework of vertical and horizontal steel pipes that pre-determine the essential curvature of the wall to which the blocks confirm. A plywood grid, or analogue wall form, was used during construction as a supporting shape and scaffold in order to precisely position each block in the curving sequence.

Three steel windows are inserted within the block wall, providing light and views to the street from the new, executive office and conference space directly behind it. The windows are first imagined as simple, orthogonal shapes in the curving wall elevation. The frames are then modified to taking the consequence of the curving surface, so that the steel frames incline in and out, following the a priori curved section of the wall as straight line analogues. The glass is then triangulated to fit within the folded steel edges of the frames.

As the block wall shape loops over the roof line, a clear-story window, invisible from the street, is positioned between the curving top of the new wall and the existing warehouse roof below, admitting natural light from the south onto the curving interior surface of the blocks.